| Metering Tube | Molded polysulfone |

| Internal Components | 316L SS, Teflon, Polysulfone or Hastelloy® C-276 |

| Fitting Material | Standard: 316L SS |

| Optional: PVC, PVDF | |

| Inlet/Outlet Fittings | FNPT, vertical |

| O-Ring | Standard: Viton® |

| Optional: Buna N, EPR, and Kalrez® | |

| Case and Shield | 304 SS case |

| Polycarbonate Shield |

Performance

| Capacities | Water (Teflon® float) 0.5 to 100 GPM | |

| Water (Metal float) 1.5 to 160 GPM | ||

| Air 6.1 to 330 SCFM | ||

| Scale | 127 mm (5″) direct reading, detachable | |

| Accuracy | ± 3% of full scale flow | |

| ± 5% of full scale flow | ||

| (120 & 150 GPM Metal floats) | ||

| ± 6% of full scale flow (Teflon® floats) | ||

| Turndown | 10:1 | |

| Repeatability | 1/2% | |

| 1% (120 & 150 GPM Metal floats) | ||

| 1% (Teflon® floats) | ||

| Maximum Temperature | 316L SS fittings 200° F (93° C) | |

| PVC fittings 130° F (54° C) | ||

| Maximum Pressure | 316L SS fittings | 200 psig |

| PVC & PVDF fittings | 150 psig | |

| (sizes 41W to 72W) | ||

| PVC & PVDF fittings | 125 psig | |

| (sizes 90W to 103W) | ||

| Ambient Temperature | 33° F to 125° F (1° C to 52° C) | |

Options

| Alarm | Latching Reed Switch |

| Certified Calibrations | Conform to ISA RP 16.6 |

| Scales | Any volumetric unit |

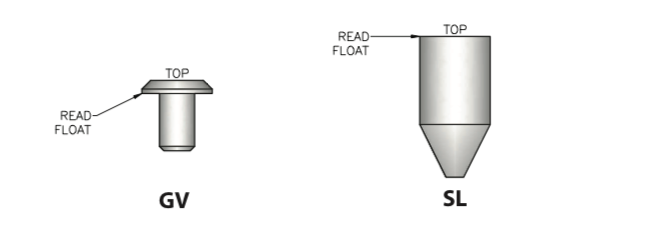

Floats

Options for rotameter float materials and designs extend flow ranges for different fluids within a given rotameter tube design.