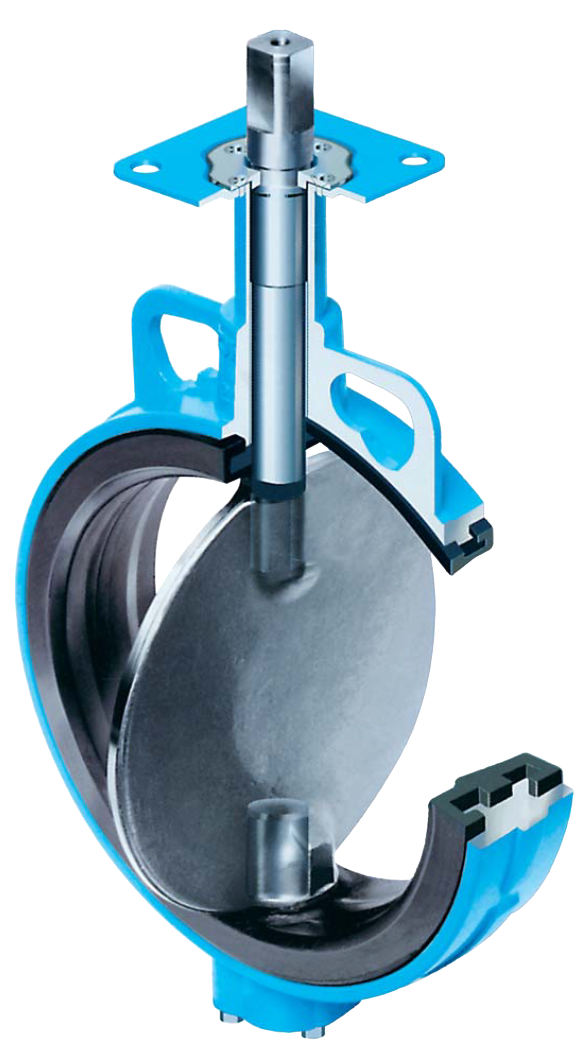

OKM 602A BUTTERFLY VALVE

Rubber Seated Butterfly Valve

Applications

Air-conditioning systems, water treatment, general industries

Actuators

Lever, gear, cylinder, electric motor

○ Piping flanges: JIS 5K, 10K

○ Production size: 40 A to 300 A

Integrated aluminum valve body and stainless-steel neck

Condensation-resistant JIS-compliant valve

This valve uses an integrated design with lightweight, solid aluminum die-casting and a stainless-steel neck. The unique structure of this JIS-compliant aluminum die-cast butterfly valve provides excellent resistance to condensation.

Excellent corrosion resistance and long service life of wetted parts

The wetted parts of this valve offer excellent corrosion resistance for a strong, long service life for fluids such as tap water mixed with bactericides or other additives. For even better handling of such fluids, the disc is made of stainless steel, and the seat is made of durable rubber.

Dual-purpose deviation-proof and JIS 5K or 10K piping guide

Using OKM’s proprietary “T-bar” in the bolt guide hole makes positioning of the piping easy and reliable. This eliminates the need to worry about misalignment all together.